FRAME EXTRUSION

Usage – the most commonly used frame, good value for money, suitable for heavy traffic loads.

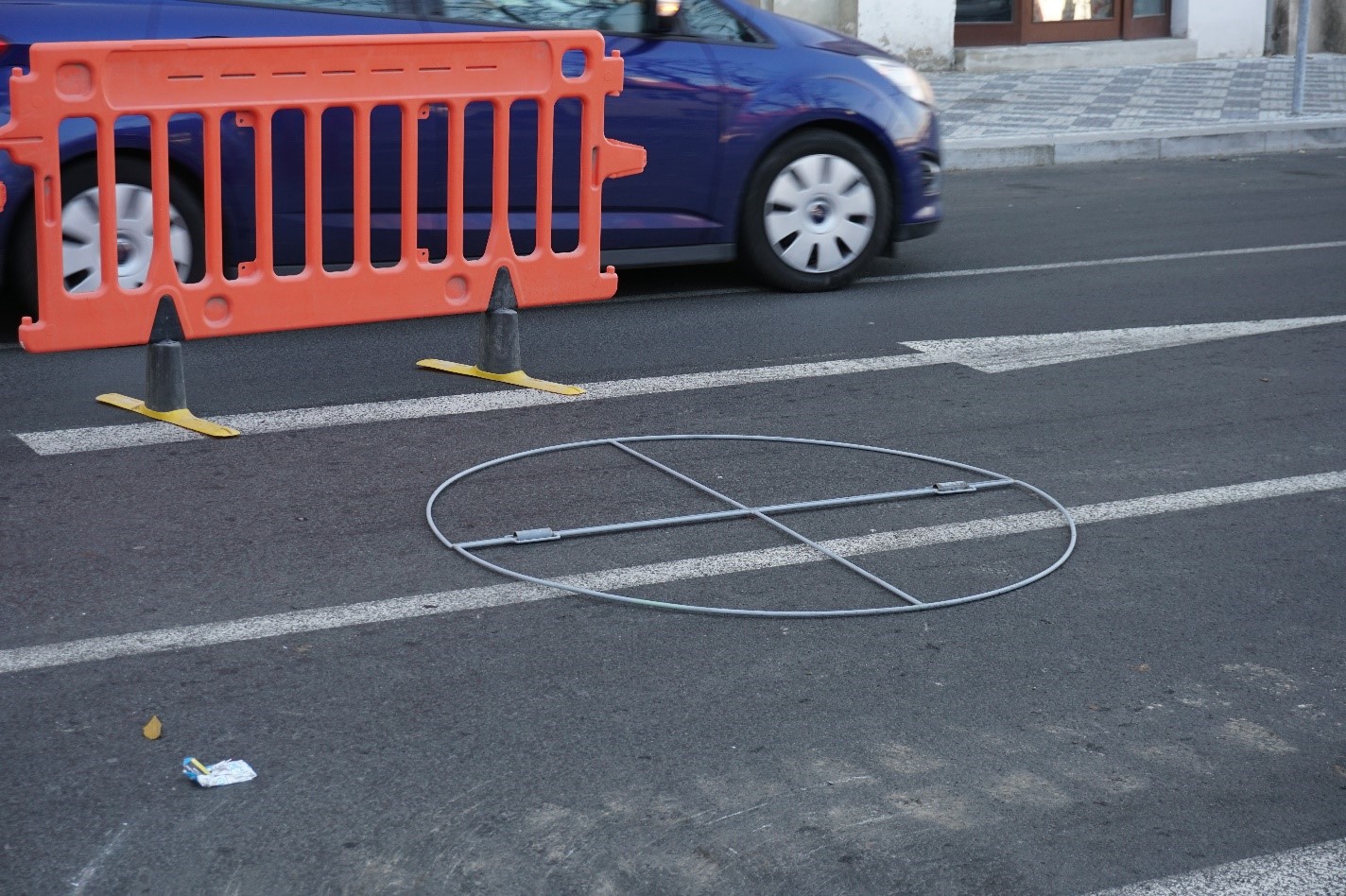

1. Marking the hatch location

- The work with the installation of the manhole cover starts after completion of the road

- The centre of the temporary hatch, the slab under the asphalt, is located by coordinates and the cut-out is marked.

2. Demolition

- Uncover part of the hatch so that the lid can be removed

- Clean the lid

3. Preparation for extrusion

- Remove the lid

- Clean the frame and check the joint between the frame and the shaft

4. Machine set-up

- Hydraulic machine with fixed edge for frame extrusion

- Centre it exactly above the hole

5. Machine operation

- The four spikes go under the frame and pull up the edges so that the hatch is perfectly level with the road

- Remove the extracted asphalt

6. Gap

- The key is used for immediate height fixation

- The resulting joint is cleaned

7. Formwork

- The frame locks into the plane

- Inflatable formwork with funnels is inserted

8. Grout

- Grout with high-strength and resistance to chemical defrosting agents

- After a very short time, the rapidly solidifying mass is ready for further processing

9. Completion

- Refit the cleaned lid

- After gap treatment, the result is a hatch in an ideal plane with the road

Spravovat Souhlas

Abychom poskytli co nejlepší služby, používáme k ukládání a/nebo přístupu k informacím o zařízení, technologie jako jsou soubory cookies. Souhlas s těmito technologiemi nám umožní zpracovávat údaje, jako je chování při procházení nebo jedinečná ID na tomto webu. Nesouhlas nebo odvolání souhlasu může nepříznivě ovlivnit určité vlastnosti a funkce.

Funkční Always active

Technické uložení nebo přístup je nezbytně nutný pro legitimní účel umožnění použití konkrétní služby, kterou si odběratel nebo uživatel výslovně vyžádal, nebo pouze za účelem provedení přenosu sdělení prostřednictvím sítě elektronických komunikací.

Předvolby

Technické uložení nebo přístup je nezbytný pro legitimní účel ukládání preferencí, které nejsou požadovány odběratelem nebo uživatelem.

Statistiky

Technické uložení nebo přístup, který se používá výhradně pro statistické účely.

Technické uložení nebo přístup, který se používá výhradně pro anonymní statistické účely. Bez předvolání, dobrovolného plnění ze strany vašeho Poskytovatele internetových služeb nebo dalších záznamů od třetí strany nelze informace, uložené nebo získané pouze pro tento účel, obvykle použít k vaší identifikaci.

Marketing

Technické uložení nebo přístup je nutný k vytvoření uživatelských profilů za účelem zasílání reklamy nebo sledování uživatele na webových stránkách nebo několika webových stránkách pro podobné marketingové účely.